loads on brinell hardness test|brinell hardness test chart : mail order The Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. Melhores Vídeos +18 Vazados do Telegram. [Canal] Hot Novinhas 88.2K members. Melhores Vídeos +18 Vazados do Telegram

{plog:ftitle_list}

Resultado da Ranger777, Cassino Slots! Venha se divertir em Nossa Plataforma de Jogos! PG game, PP game e Muito Mais! Ranger777, Cassino Slots! Venha se .

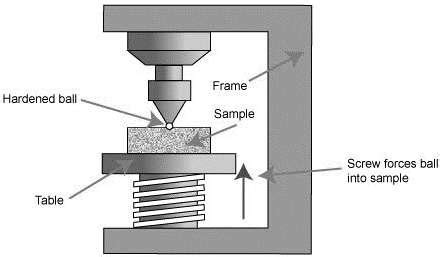

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and . Above you can see the diagram of Brinell hardness testing machine equipped with various loads and multiple ball indentors. A load selecting knob is used to change the size of the load. The lever is used to .

When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the .The Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and .According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the Brinell hardness (HBW).

brinell hardness tester diagram

Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .The Brinell method has a test load range of 1 to 3000 kgf, which means that this method can be used for hardness testing in the low-load and, above all, macro ranges (conventional range). It .

loaded 1911 dropping test

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons. However, the general rule is that the .BHN = Brinell Hardness Number. P = load on the indenting tool (kg) D = diameter of steel ball (mm) d = measure diameter at the rim of the impression (mm) It is desirable that the test load are limited to a impression diameter in the range of 2.5 to 4.75 mm. Approximate loads and Brinell Hardness Numbers:A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.

brinell hardness test theory

Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. In brinell testing machine the load is applied by a lever mounted on knife edges and carrying a hanger for suspending the required load. The supporting table for .Characteristics of hardness testing methods for applied load F. Brinell hardness, BHN = 2F/πD [D − (D 2 − d 2) 1/2]. Vickers hardness, H v . Brinell Hardness (HB) test is expressed by the pressure loaded on the press mark per unit area. The hardness of natural minerals is often tested by scratch hardness. Mineral hardness is divided into .When is the Brinell hardness test used? Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested.

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus pretends a softer material. (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with .

The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. . leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material .The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:

Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings.

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell Hardness Number HB is computed from the equation: where P is the applied load of 3,000, 1,500, or 500kg. D is the diameter of the ball in mm. (10mm)

The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. . Officially, hardness testing loads are expressed in Newton (N). However, historically, loads were .

The Brinell hardness test consists of applying a constant load or force, usually between 187.5 and 3000Kgf, for a specified time (from 10 – 30 seconds) typically using a 2.5 or 10mm diameter tungsten carbide ball (see .The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with .The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

local companies dropping pot from drug tests

A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and forgings that may have rough surfaces or exhibit some chemical variation. Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative .Explanation: Brinell hardness test uses ball indenter. Its diameter is kept 1 mm for lower load 1 kgf. It is taken 10 mm for 500 kgf load. 7. Brinell hardness number is not a function of _____ . Explanation: In Brinell test load is applied for a standard time. It is generally 30 second. Unloading is carried out after this duration.

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the .

Brinell Hardness Test Blocks — ASTM E-10 and ISO 6506. All of our Brinell Test Blocks come certified to applicable standards. We adhere to a strict procedure for the calibration of these blocks, and the accuracy of the tester is maintained using a proving ring and load cell both traceable to N.I.S.T. . Brinell 500kg Load: All Hardness .2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is measured to calculate the Brinell hardness number (HB). This method is ideal for testing softer or larger materials like cast iron and steel.The Brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (ISO 6506, ASTM E10). The Brinell method has a test load range of 1 to 3000 kgf, which means that this method can be used for hardness testing in the low-load and, above all, macro ranges (conventional range).

brinell hardness test pdf

Brinell Hardness Testing Vickers Hardness Testing . The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. . an additional load, call the major load, is added to reach .Other articles where Brinell hardness test is discussed: Johan August Brinell: .Swedish metallurgist who devised the Brinell hardness test, a rapid, . uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS. Much smaller loads and diamond microindenters also can be used in conjunction .

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is .

local drop in covid testing near me

lockheed p-80 drop test

Resultado da Apuestas deportivas online en Betfair. Regístrate hoy para obtener las mejores cuotas de apuestas deportivas en fútbol, baloncesto, tenis y otros deportes.

loads on brinell hardness test|brinell hardness test chart